- +86 18691706868

- fang860503@163.com

- 27 Xi Guo Da Dao Baoji, Shaanxi, China

Primarily used for heating and vacuum annealing of titanium tubes under vacuum conditions.

Externally heated titanium tube vacuum annealing furnace | ||

Parameters / Model | ZR12G | ZR13G |

Maximum temperature | 850℃ | 850℃ |

Normal operating temperature | 500~800℃±5℃ | 500~800℃±5℃ |

Effective working temperature zone | φ800×12000㎜ | φ800×13000㎜ |

Maximum loading capacity | Maximum 950 kg / furnace | Maximum 1050 kg / furnace |

Annealing tube size | φ 12 —φ 114 ×δ 0.5~ δ 4 × 12000 ㎜ | φ 12 —φ 114 ×δ 0.5~ δ 4 × 13000 ㎜ |

Ultimate vacuum | 2.0 × 10-1 Pa | 2.0 × 10-1 Pa |

Pressure rise rate | Not more than 1 Pa/h | Not more than 1 Pa/h |

Working vacuum exhaust time | ≦30min | ≦30min |

Heating power | Zone 6 , 390KW | Zone 6 , 410KW |

Cart moving speed | 5m/min | 5m/min |

Temperature control accuracy | ±1℃ | ±1℃ |

Furnace temperature uniformity | ≤±5℃ | ≤±5℃ |

Suitable for atmospheric annealing and leveling of medium and thick plates of titanium and titanium alloys.

Pit-type electric heating annealing furnace | ||

Parameters / Model | DKR856-8 | DKR856-6 |

Furnace inner dimensions | 3600*8600* ( 5+200+80 ) | 3600*6600* ( 5+200+80 ) |

Furnace bottom plate size | 2900*8300*100 | 2900*6300*100 |

Design temperature | 500~850 ℃ | 500~850 ℃ |

Heating power | 1070KW | 856KW |

Temperature control accuracy | ≤± 2 ℃ ( 9 -zone temperature control) | ≤± 2 ℃ ( 9 -zone temperature control) |

Temperature uniformity | ± 10 ℃ | ± 10 ℃ |

Average heating rate | Room temperature rise 800 ℃ ≤ 5 hours | Room temperature rise 800 ℃ ≤ 5 hours |

Heating elements | 0Cr25Al5 | 0Cr25Al5 |

Installation dimensions | 9.8m × 4.8m × 1.4m | 7.8m × 4.8m × 1.4m |

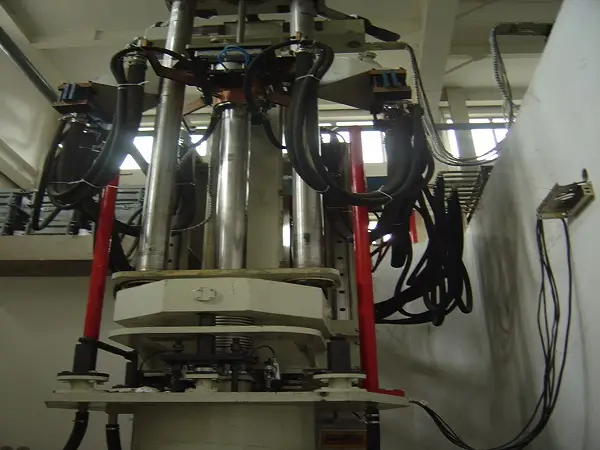

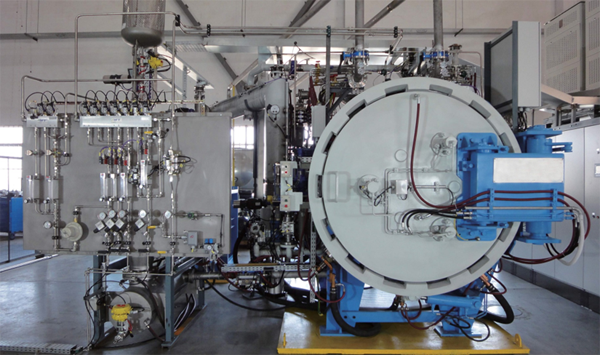

This automatic welding equipment is used to weld titanium and titanium alloy sponge material blocks into electrodes. Sponge titanium is pressed into small blocks weighing 200-300kg using a hydraulic press. Subsequently, it must be welded into electrodes weighing 3000-15000kg before smelting. Electrode welding is an essential process step in sponge titanium smelting.

Vacuum plasma automatic welding equipment plays an essential role in the titanium industry’s smelting process. Fully automatic vacuum plasma welding equipment is easy to operate and features a one-touch start function that automatically completes the welding process.

Vacuum plasma welding box | ||

Parameters \ Model | DLX-12T/3 | DLX-5T/2 |

Loading weight ( kg ) | 12T | 5T |

Number of welding guns | 3 | 2 |

Welding speed | 50-100mm/min | 50-100mm/min |

Argon flow rate during welding | 5-30L/min | 5-30L/min |

Weld depth | 10-25mm | 10-25mm |

Weld width | 30-50mm | 30-50mm |

Work Environment | Vacuum +Ar | Vacuum +Ar |

Ultimate vacuum pressure | 1Pa | 1Pa |

Working pressure ( Pa ) | 30000-60000Pa | 30000-60000Pa |

Pressure rise rate ( Pa/h ) | 0.67 | 0.67 |

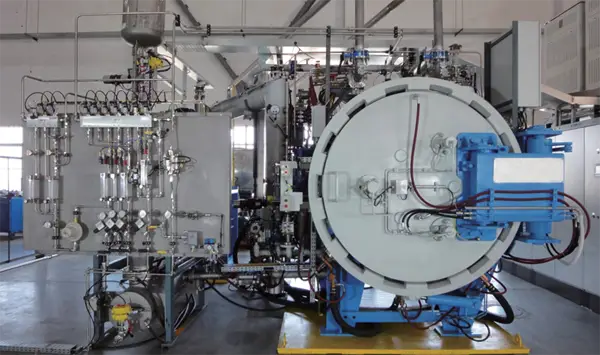

Vacuum creep leveling furnace is used to correct the shape of titanium thin and thick plates and eliminate the hardness. In aviation and aerospace , titanium plates must meet the flatness requirements and completely eliminate the internal hardness of the material.

No other method for leveling or eliminating stiffness in titanium plates can guarantee complete elimination of stiffness. Therefore, only the vacuum creep process can achieve these goals. my country’s aerospace and aviation industries are currently developing, and so are titanium plate leveling equipment for aerospace applications. Dingsheng Company is currently the leading manufacturer of titanium plate leveling equipment in the domestic market.

Vacuum creep leveling | ||

Parameters \ Model | ZRL-10000 | ZRL-8000 |

Working area dimensions width × height × depth ( mm ) | 9400 × 3400 × 100 | 7400 × 3400 × 100 |

Loading weight ( kg ) | < 10000Kg (workpiece + pad, pressure plate) | < 21000Kg (workpiece + pad, pressure plate) |

Maximum temperature (℃) | 500~750 ℃ | 500~750 ℃ |

Temperature uniformity (℃) | ± 10 ℃ | ± 10 ℃ |

Heating power ( kW ) | 1250kw | 1000kw |

Work Environment | vacuum | vacuum |

Thermal vacuum degree ( Pa ) | 3.8 × 104 ~5 × 104 Pa | 3.8 × 104 ~5 × 104 Pa |

Orthopedic pressure | P ≥ 5t/m2 | P ≥ 5t/m2 |

*Customized design and manufacturing can be made according to customer needs

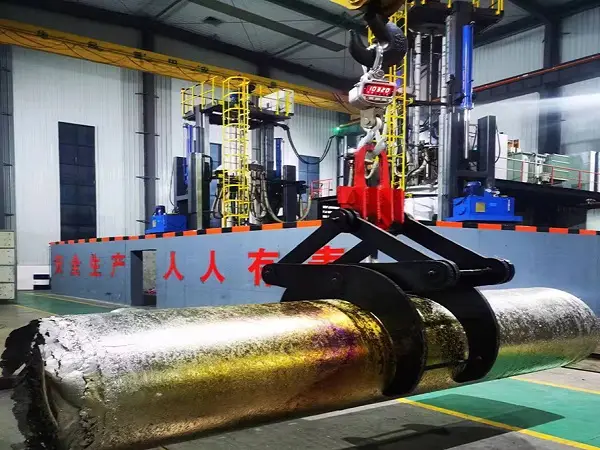

Using electric arc to heat and melt metal in a vacuum , mainly used to melt rare metals such as titanium and titanium alloys, zirconium and zirconium alloys.

Vacuum Consumable Electrode Arc Furnace

| Parameter / Model | ZHT02 | ZHT30/50 | ZHT100 | ZHT150 |

|---|---|---|---|---|

| Maximum Ingot Weight (kg) | 200 | 3000 / 5000 | 10000 | 15000 |

| Maximum Ingot Size (mm) | φ210×1700 | φ640×2700 / φ720×3500 | φ1040×3500 | φ1160×3800 |

| Maximum Melting Current (A) | 8000 | 24000 / 30000 | 40000 | 48000 |

| Ultimate Vacuum in Chamber (Pa) | 6×10⁻² | 6×10⁻² | 6×10⁻² | 6×10⁻² |

| Working Vacuum (Pa) | 0.1~10 | 0.1~10 | 0.1~10 | 0.1~10 |

| Pressure Rise Rate (Pa/h) | 0.67 | 0.67 | 0.67 | 0.67 |

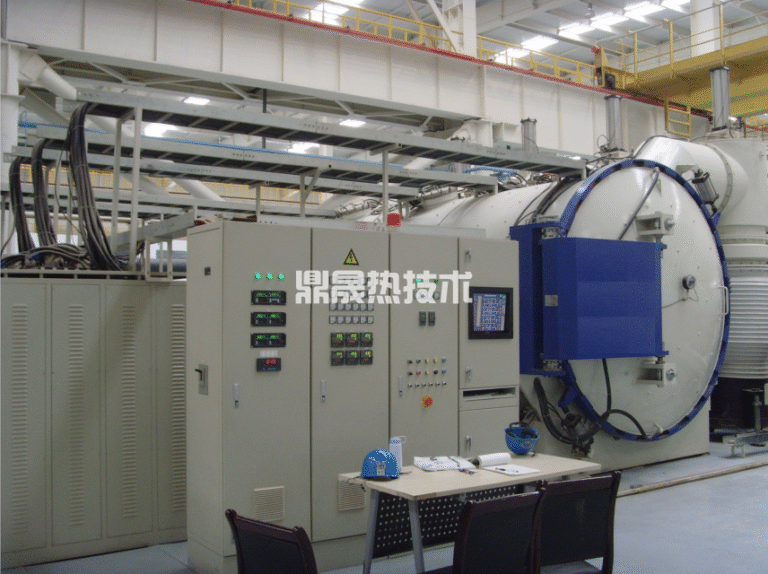

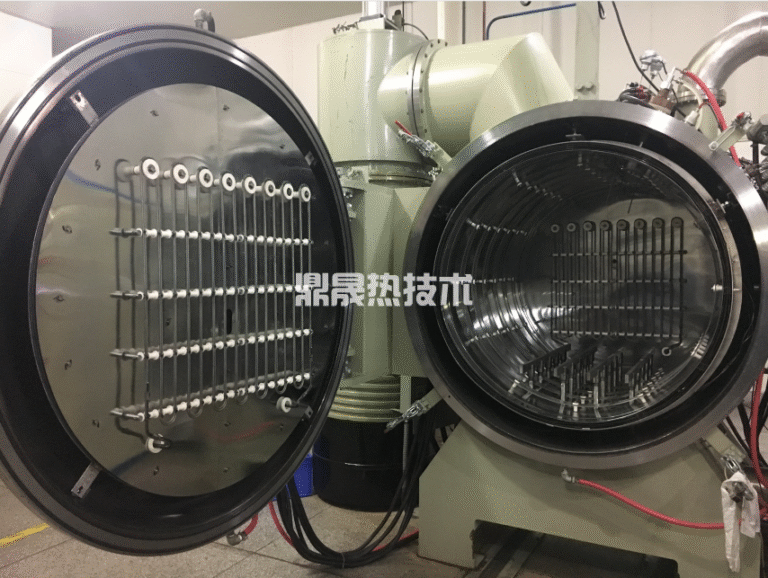

Vacuum Annealing of Thin Titanium Sheets

Titanium plate horizontal vacuum annealing furnace | ||

Parameters\Model | ZTL-3000 | ZTL-6000 |

Type | Single-chamber horizontal type, external circulation fast cooling, full automatic/manual interlock control | Single-chamber horizontal type, external circulation fast cooling, full automatic/manual interlock control |

Working area dimensions width × height × depth (mm) | 1600 (1800) × 540 × 3000 | 1600 (1800) × 800 × 6000 |

Loading weight (kg) | <10000Kg (workpiece + pad, pressure plate) | <21000Kg (workpiece + pad, pressure plate) |

Maximum temperature (℃) | 950 ℃ | 950 ℃ |

Temperature uniformity (℃) | ±5 | ±5 |

Heating power (kW) | 800 | 1200 |

Work Environment | Vacuum, Ar | Vacuum, Ar |

Cold ultimate vacuum (Pa) | Better than 1×10-3Pa (empty furnace) | Better than 1×10-3Pa (empty furnace) |

Thermal vacuum degree (Pa) | Better than 1.1×10-2Pa (after keeping in an empty furnace at 850℃ for 1h) | Better than 1.1×10-2Pa (after keeping in an empty furnace at 850℃ for 1h) |

Pressure rise rate (Pa/h) | ≤ 0.67Pa/h | ≤ 0.67Pa/h |

Sintering of aluminum nitride ceramic substrates

| |||||||||||||||||||||||||||||||||||||||||||||||

Cemented Carbide, Powder Metallurgy, and Pressure Sintering of Silicon Nitride Ceramics.

| |||||||||||||||||||||||||||||||||||||

Transparent Ceramic Sintering

| Parameter / Model | ZK-150 | ZK-350 | ZK-500 | ZK-600 |

|---|---|---|---|---|

| Working Area Size φ×L (mm) | φ150×200 | φ350×400 | φ500×600 | φ600×700 |

| Loading Weight (kg) | 200 | 300 | 400 | 600 |

| Maximum Temperature (℃) | 2200 | 2200 | 2200 | 2200 |

| Temperature Uniformity (℃) | ±2 | ±5 | ±5 | ±5 |

| Heating Power (kW) | 50 | 120 | 200 | 230 |

| Ultimate Vacuum (Pa) | 5×10⁻⁵ Pa | 5×10⁻⁵ Pa | 5×10⁻⁵ Pa | 5×10⁻⁵ Pa |

| Pressure Rise Rate (Pa/h) | 0.5 | 0.5 | 0.5 | 0.5 |

Surface metallization of ceramics, hydrogen-atmosphere sintering in powder metallurgy, oxygen-free heat treatment of materials, surface purification, and other related fields in the electronics industry.

| Parameter / Model | ZK-500 | ZK-600 |

|---|---|---|

| Working Area Size φ×L (mm) | φ500×800 | φ600×900 |

| Loading Weight (kg) | 500 | 600 |

| Maximum Temperature (℃) | 1100–1600 | 1100–1600 |

| Temperature Uniformity (℃) | ±5 | ±5 |

| Heating Power (kW) | 200 | 230 |

| Working Atmosphere | H₂, N₂ | H₂, N₂ |

| Ultimate Vacuum (Pa) | 1000 Pa | 1000 Pa |

| Pressure Rise Rate (Pa/h) | 0.67 | 0.67 |

Pressure sintering of cemented carbide, powder metallurgy, and silicon nitride ceramics

| Model | Feed Size (mm) | Inner Chamber Size (mm) | Heating Power (kW) | Working Pressure |

|---|---|---|---|---|

| DSTT-90 | 500 × 500 × 900 | 800 × 1175 | 600 | ≤10 MPa |

| DSTT-150 | 500 × 500 × 1500 | 800 × 1780 | 690 | ≤10 MPa |

| DSTT-180 | 500 × 500 × 1800 | 800 × 2100 | 740 | ≤10 MPa |

| DSTT-230 | 500 × 500 × 2300 | 800 × 2600 | 940 | ≤10 MPa |

| DSTT-270 | 500 × 500 × 2700 | 800 × 3010 | 1140 | ≤10 MPa |

| DSTT-300 | 500 × 500 × 3000 | 800 × 3310 | 1200 | ≤10 MPa |

Vacuum brazing, vacuum sintering, vacuum annealing, and MIM (Metal Injection Molding) part sintering.

| Parameter \ Model | DS-1200 | DS-1500 | DS-2000 | DS-3000 | DS-5000 |

|---|---|---|---|---|---|

| Working Zone Size (W×H×L, mm) | 600×400×1200 | 800×500×1500 | 1000×600×2000 | 1500×900×3000 | 2000×1200×5000 |

| Loading Weight (kg) | 500 | 800 | 1000 | 4000 | 1000 |

| Maximum Temperature (℃) | 1450 | 1450 | 1450 | 1450 | 1450 |

| Temperature Uniformity (℃) | ±5 | ±5 | ±5 | ±8 | ±8 |

| Heating Power (kW) | 230 | 260 | 280 | 450 | 800 |

| Ultimate Vacuum (Pa) | 5×10⁻⁴ | 5×10⁻⁴ | 5×10⁻⁴ | 5×10⁻⁴ | 5×10⁻⁴ |

| Leak Rate (Pa/h) | 0.67 | 0.67 | 0.67 | 0.67 | 0.67 |

Aluminum nitride sintering, powder metallurgy materials, aerospace materials, and metal heat treatment

| Parameter / Model | ZK-150 | ZK-350 | ZK-460 | ZK-600 |

|---|---|---|---|---|

| Working Zone Size φ×L (mm) | φ150 × 200 | φ320 × 350 | φ460 × 600 | φ600 × 700 |

| Loading Capacity (kg) | 200 | 300 | 400 | 600 |

| Maximum Temperature (℃) | 2500 | 2500 | 2500 | 2500 |

| Temperature Uniformity (℃) | ±2 | ±5 | ±5 | ±5 |

| Heating Power (kW) | 50 | 120 | 260 | 280 |

| Ultimate Vacuum (Pa) | 5×10⁻⁵ Pa | 5×10⁻⁵ Pa | 5×10⁻⁵ Pa | 5×10⁻⁵ Pa |

| Pressure Rise Rate (Pa/h) | 0.5 | 0.5 | 0.5 | 0.5 |

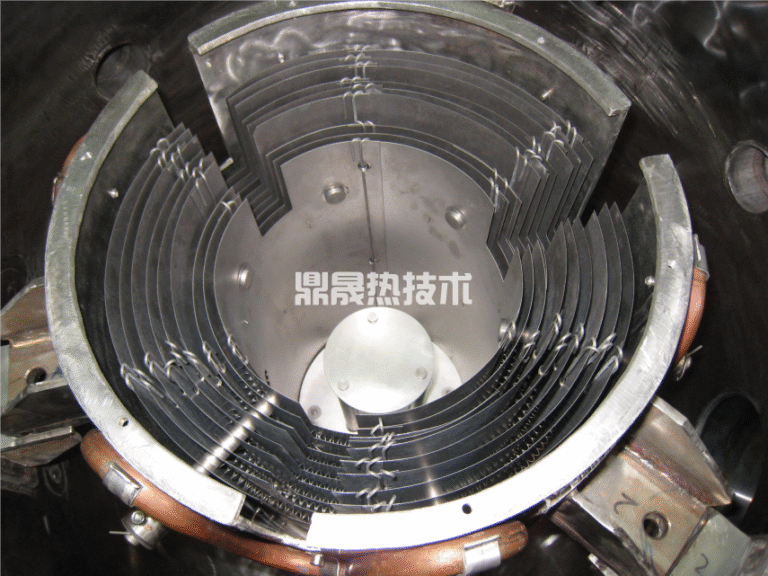

Provide users with annealing furnace modification and design solutions in various specifications and sizes, to improve temperature uniformity and extend the overall service life of the heating field.

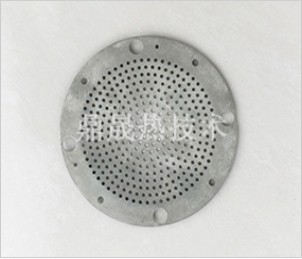

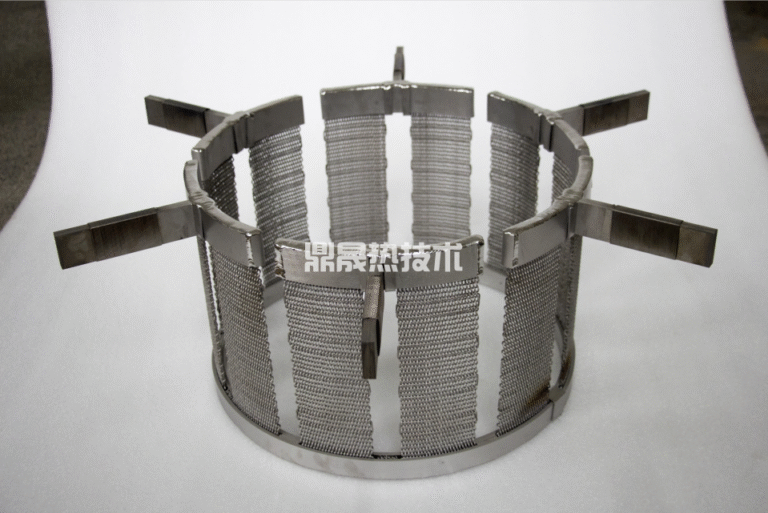

As a core component, it is widely used in various types of vacuum resistance furnaces. It features high heating efficiency, stable quality, and a long service life.

| Material | Material | Material | Material | Material | Material | Material | Material |

|---|---|---|---|---|---|---|---|

| Type | Spiral Mesh | Plain Weave Mesh | Tungsten Disc | Tungsten Tube | Tungsten Bundle | Tungsten Cage | Tungsten Arch |

| Dimensions (mm) | φ80 × 200 / φ200 × 450 / φ600 × 1200 | φ250 × 250 × 400 / φ50 × 500 × 1000 | φ100 × 310 / φ200 × 500 / φ500 × 1000 | φ35 × 3500 / φ200 × 1000 | Tungsten Bundle φ100 × 350 / φ500 × 600 / φ1400 × 1800 | φ3 × 3 × 180 / φ300 × 1000 | φ40 × 40 × 500 / R10–R300 |

| Operating Temperature (°C) | 2300–2700 | 2300–2700 | 2300–2600 | 2300–2600 | 2000–2300 | 2000–2300 | 2000–2300 |

| Connection Type | Single-phase / Three-phase | Single-phase / Three-phase | Single-phase / Three-phase | Single-phase | Single-phase | Single-phase | Single-phase |

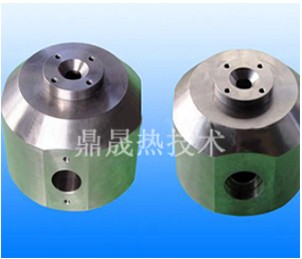

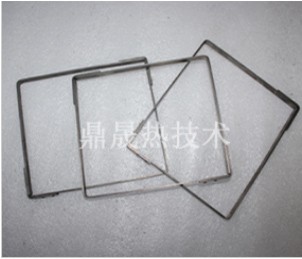

Custom Machined Parts Made to Customer Specifications

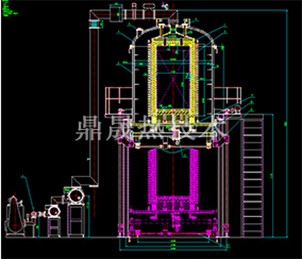

Furnace body assembled and welded on-site using various medium and large steel profiles; outer casing panels made of color steel, solid and attractive.

Furnace lining uses mullite refractory full-fiber insulation, about 40% more energy-efficient than traditional brick-type chambers.

Trolley frame welded from large I-beams, channel steel, angle steel, and thick steel plates; movement driven by electric motor with worm gear reducer and chain drive; refractory structure made of high-alumina shaped bricks; soft-contact sealing with labyrinth sand seal and sand seal knife device.

Furnace door is side-opening type, sealed with hand-wheel pressing mechanism.

Combustion system with dozens of small burners on both sides; multi-burner, low-heat-flow circulation ensures uniform temperature; burners have automatic ignition and instrument control.

Exhaust system installed at the upper rear with adjustable valve plate to regulate furnace pressure.

Control system is simple and practical interlock type, with digital temperature display and contactor control; non-standard design fully customized per user requirements.

Temperature control system, vacuum system, and power supply system

Automatic heating; real-time display of heating curves; automatic control.

Temperature control accuracy ≤ ±1℃.

Uses HONEYWELL PlantScape Vista/HC900 integrated control system (DCS).

Equipped with a Windows NT/2000-based host computer.

HC900 processor supports local and remote dial-up configuration/diagnosis, Ethernet 10Base-T for point-to-point communication with up to 5 host computers and 8 control processors, 4 remote expansion boxes, and RS485 master/slave communication.

Software uses HONEYWELL industrial flexible manufacturing control package with open standards (OPC, ODBC, advanced DDE) for monitoring.

Computer monitoring station provides a complete user environment supporting operations, process analysis, system maintenance, and configuration.

Offers simple, intuitive user interface, historical data, reports, alarm management, and operational/process graphics.

Strong data processing capability supports product analysis and new product development.

All process parameters can be stored on the hard drive; industrial computer-based monitoring enhances system reliability and safety.

Loading Method: Lifting-type unloading or top loading.

Furnace Shell: Vacuum chamber made of high-temperature resistant stainless steel.

Insulation Layer: Zirconia and alumina.

Heater: Induction heating.

Process Gas System: Volumetric/mass flow meters; manual or automatic valves; imported or domestic components.

Vacuum Pump and Vacuum Gauge: Imported or domestic.

Human-Machine Interface (HMI): Analog screen, touch screen, or industrial PC.

PLC: Honeywell DCS controller, Siemens PLC, Omron PLC.

Temperature Control: Honeywell DCS controller, Japanese conductivity instruments, Honeywell instruments, Eurotherm instruments.

Thermocouple: Infrared or conventional thermocouple type.

Electrical Components: Tengen, Chint, Schneider, Siemens.

Loading Method: Lifting-type unloading or top loading.

Furnace Shell: Vacuum chamber made of high-temperature resistant stainless steel.

Insulation Layer: Graphite.

Heater: Induction heating.

Process Gas System: Volumetric/mass flow meters; manual or automatic valves; imported or domestic components.

Vacuum Pump and Vacuum Gauge: Imported or domestic.

Human-Machine Interface (HMI): Analog screen, touch screen, or industrial PC.

PLC: Honeywell DCS controller, Siemens PLC, Omron PLC.

Temperature Control: Honeywell DCS controller, Japanese conductivity instruments, Honeywell instruments, Eurotherm instruments.

Thermocouple: Infrared or conventional thermocouple type.

Electrical Components: Tengen, Chint, Schneider, Siemens.