Baoji has a company that “plays” with equipment — and it’s doing quite well!

The name Dingsheng carries cultural meaning: “Ding” (鼎) refers to bronze tripods, a symbol of Baoji’s long-standing combination of metal and culture; “Sheng” (晟), a combination of “sun” and “success,” implies that success will inevitably come. When the reporter talked with General Manager Liu Yunfei about the name, his explanation reflected the company’s deep-rooted ambition.

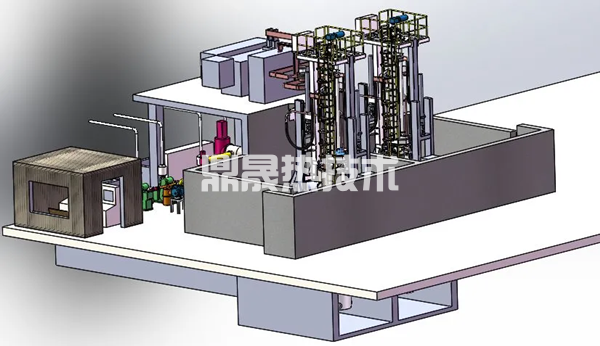

Dingsheng Vacuum Thermal Technology Co., Ltd. (referred to as Dingsheng Vacuum) is a small enterprise: fewer than 30 staff and management, and only four years old. The management team consists mostly of 70s and 80s generation: Liu Yunfei (70s), Fang Yangyang, Zhang Chunsheng, Qi Yajun, and Gao Guoqiang (80s). Despite its small size, this micro-enterprise impresses — it manufactures high-end industrial equipment.

In production sites, arcs flash and cranes move as equipment is rapidly being built. When asked whether all the equipment is developed in-house, management confirmed: Dingsheng Vacuum specializes in equipment development and manufacturing, emphasizing technical expertise as its core. Equipment manufacturing is like “hard currency” — excelling in a niche can make a company a leader in its field, just like the Netherlands’ lithography machines.

2020 was a challenging year due to the pandemic, and many titanium enterprises struggled, yet Dingsheng Vacuum thrived. In 2019, its revenue was about 18 million RMB, while 2020 orders exceeded 35 million RMB, with 2021 orders already being signed. According to the youngest manager, Fang Yangyang, the production scene is simply “busy!”

Company Highlights & Innovations:

- 2017: Dingsheng Vacuum developed a vacuum creep leveling furnace for aerospace titanium plates. They are the only private enterprise capable of producing a complete set.

- 2018: They broke through fully automatic vacuum plasma welding box technology. Their fully automatic welders cost only one-third of imported equivalents, with some consumables lasting longer than imports. One-button operation makes it far easier than semi-automatic, manually operated welders.

- 2019: Introduced continuous vacuum titanium tube annealing furnaces, including 13m continuous and 20m single-furnace models — the longest in China. These replace imported Japanese equipment. The three-chamber design allows preheated, constant-temperature middle sections and alternating cooling ends, improving efficiency and reducing power consumption compared to single-chamber furnaces.

- 2020: Launched 5–8 ton VAR vacuum consumable arc furnaces, with customization options for 8–10+ ton capacities. They can also manufacture 2000–2500℃ high-temperature metal thermal equipment.

All of Dingsheng Vacuum’s high-temperature equipment, including creep furnaces, plasma welding boxes, annealing furnaces, and VAR furnaces, is produced successfully in one go. Their equipment is already used by CAS Institute of Metals, Jiangsu Wotai, Xinjiang Xiangsheng, Baoji Julong, Jucheng Titanium, and others.

Takeaways from the Interview:

The company motto, “eat technical food, walk the technical path,” reflects their philosophy: focus on mastering technology and delivering high-quality results. Their 70s and 80s management team prioritizes technical precision and quality control. Liu Yunfei emphasizes making China’s high-temperature furnace equipment the best domestically and aims at serving high-end domestic enterprises.

By opening their vision and building technical expertise, Dingsheng Vacuum is poised to succeed, embodying the principle of “success will inevitably come.”